Precision Engineering Revolution: Singapore’s Manufacturing Excellence

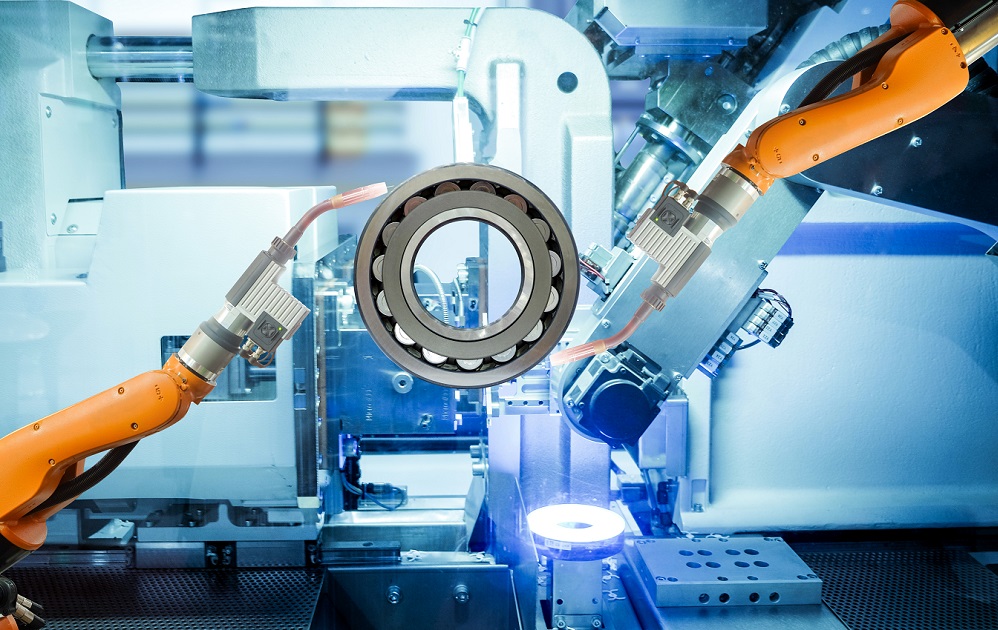

In the heart of Southeast Asia’s manufacturing landscape, an AMT – metal injection molding manufacturer stands as a testament to precision engineering’s transformative power, where complex metal components emerge from the fusion of innovation and meticulous craftsmanship. This sophisticated manufacturing process has quietly revolutionised how industries approach the creation of intricate metal parts, offering solutions that bridge the gap between design ambition and manufacturing reality.

Understanding Metal Injection Molding: Where Art Meets Science

Metal injection molding represents a remarkable convergence of two established technologies: plastic injection molding and powder metallurgy. This advanced manufacturing solution enables the production of complex geometries that would challenge traditional machining methods, whilst maintaining exceptional precision and material properties. The process begins with fine metal powders, typically less than 20 micrometres, combined with thermoplastic binders to create a feedstock that flows like honey through injection molding machinery.

The elegance lies in its simplicity: what emerges as a “green part” undergoes careful debinding to remove the polymer binders, followed by sintering at precisely controlled temperatures. During this final stage, the metal particles fuse, creating components with densities approaching 98% of wrought materials. As one Singapore-based expert explains, “MIM excels at applications that require shape complexity and superior properties such as high strength, excellent magnetic permeability, good creep resistance, corrosion resistance and thermal conductivity.”

The Singapore Advantage: Where Precision Meets Innovation

Singapore’s strategic position as a global manufacturing hub has fostered an environment where metal injection molding producers thrive. The nation’s commitment to advanced manufacturing technologies, combined with world-class infrastructure and a skilled workforce, creates ideal conditions for precision engineering excellence. Local manufacturers benefit from Singapore’s robust ecosystem of research institutions, government support, and proximity to key markets across the Asia-Pacific.

Key advantages of Singapore’s MIM sector include:

- World-class quality standards with ISO 9001, ISO 13485, and IATF 16949 certifications

- Strategic location providing access to global markets

- Advanced research and development capabilities

- Skilled engineering workforce with multilingual capabilities

- Established supply chains for speciality materials and equipment

- Government support for advanced manufacturing initiatives

The sophistication of Singapore’s manufacturing landscape becomes evident when examining the breadth of materials available. From traditional carbon steels and stainless steels to exotic superalloys like Inconel and specialised compositions such as tungsten-heavy alloys, AMT metal injection molding specialists can accommodate diverse material requirements. This versatility enables applications ranging from medical implants requiring biocompatibility to aerospace components demanding extreme temperature resistance.

Industry Applications: Transforming Sectors Through Precision

The versatility of metal injection molding has created opportunities across numerous industries, each demanding specific material properties and geometric complexities. In the medical sector, surgical instruments benefit from the process’s ability to create intricate geometries whilst maintaining the biocompatibility and corrosion resistance essential for patient safety. The automotive industry leverages MIM technology for components requiring high strength-to-weight ratios, from fuel injection systems to transmission components.

Electronics manufacturers increasingly rely on precision metal injection molding services for creating miniaturised components that traditional machining simply cannot economically produce. Consider the smartphone in your pocket; it likely contains multiple MIM components, from camera housings to connector pins, each manufactured to tolerances measured in micrometres.

As industry experts note, “Metal Injection Molding (MIM) combines the precision of injection molding with powdered metal to produce highly complex metal components with exceptional mechanical properties.” This capability becomes particularly valuable in aerospace applications, where components must withstand extreme conditions whilst maintaining precise dimensional tolerances.

Material Innovation: Expanding Possibilities

The evolution of advanced metal injection molding solutions continues through material innovation. Traditional ferrous alloys, iron-based materials including carbon steels and stainless steels, remain workhorses of the industry, offering proven performance across diverse applications. However, the frontier lies in non-ferrous alloys and speciality compositions that enable previously impossible applications.

Tungsten-heavy alloys, for instance, provide exceptional density whilst maintaining workability, making them ideal for applications requiring radiation shielding or counterweight functions. Copper alloys offer superior electrical and thermal conductivity, essential for next-generation electronic components. The development of nickel-free stainless steels addresses biocompatibility concerns in medical applications, whilst superalloys enable components that function reliably in gas turbine environments.

Quality Assurance: The Foundation of Excellence

In precision manufacturing, quality transcends mere compliance; it becomes the foundation upon which entire industries rely. Singapore’s specialist metal injection molding manufacturers maintain rigorous quality systems that encompass every aspect of production, from incoming material verification through final component inspection. Advanced metrology equipment enables measurement capabilities that often exceed customer requirements, whilst statistical process control ensures consistency across production runs.

The commitment to excellence extends beyond dimensional accuracy to encompass material properties, surface finish, and functional performance. Cleanroom environments maintain the controlled conditions essential for medical device manufacturing, whilst advanced heat treatment capabilities optimise material properties for specific applications.

Future Prospects: Innovation Continues

Looking ahead, the trajectory of metal injection molding points towards increased automation, expanded material options, and enhanced precision capabilities. Singapore’s manufacturers invest continuously in advanced equipment and process development, ensuring they remain at the forefront of global manufacturing excellence.

The integration of Industry 4.0 technologies promises further improvements in process monitoring and quality assurance, whilst research into new material compositions continues to expand application possibilities. As global supply chains evolve and manufacturers seek reliable partners capable of delivering complex components with unwavering quality, Singapore’s position as a centre of excellence for precision manufacturing becomes increasingly valuable.

Through decades of dedication to manufacturing excellence, Singapore has established itself as a hub where complex engineering challenges meet innovative solutions, ensuring that when precision matters most, an AMT – metal injection molding manufacturer stands ready to deliver exceptional results.